How Golf Balls Are Made? The golf ball may be nearly nothing, yet it creeps up out of nowhere as the essential weapon in the game. The evidently simple creation of golf balls is actually the consequence of a picky technique that calls for cutting edge development, noteworthy materials, and expert craftsmanship. This article will break down the entire course of making golf balls, from the principal plan to the finished thing that causes an uproar in and out of town. Let’s read below about “How Golf Balls Are Made?”.

Understanding the Anatomy of a Golf Ball

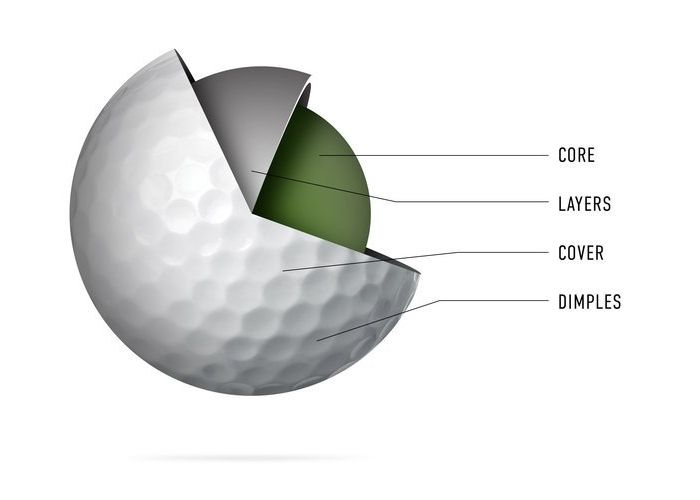

Acknowledging what goes into convincing a golf ball is principal preceding beginning the collecting framework. The praiseworthy golf ball has various layers, and each one deals with the ball’s display and life expectancy in its own uncommon way.

Core: The middle, the most central piece of a golf ball, is regularly evolved from designed versatile or gum. Compression is the primary means by which energy is transferred when a ball hits the ground; this allows the ball to move further and even more thoroughly take on its last shape.

Mantle: As it encloses the focal district, the mantle controls the center’s twist and direction. To accomplish the ideal presentation qualities, it is normal practice to involve a mix of engineered materials and added substances in the mantle.

Cover: The cover, the furthest covering of a golf ball, gives strength, feel, and streamlined execution. The two primary materials used to cover golf balls are urethane and surlyn. Durability and bend control are two locales where urethane prevails over Surlyn.

The Manufacturing Process

At each period of the creation association, golf balls require specific equipment and arranged staff. The means associated with making golf balls are illustrated in some detail in the accompanying passages, however, the specific techniques might fluctuate enormously depending upon the ball’s producer and type.

1. Design and Development

As a first stage in making golf balls, subject matter experts and materials specialists group up all through the imaginative work cycle to assess different conditions and anticipate models. Focus and dimple mixes are used in the PC to help plan programming to make the models. Contort, bearing, and distance are several of the show estimations assessed by mechanical hitting machines and ship-off screens.

2. Formulation and Mixing

Following completion of the arrangement step, a golf ball’s middle, mantle, and cover layers can be worked from different materials. To accomplish the ideal properties, like versatility, pressure strength, and solidness, engineered rubbers, pitches, and different added substances are blended and estimated in agreement in with exact recipes. High velocity blenders or working machines can be utilized to join the fixings equally and consistently.

3. Core Compression Molding

Pressure molding is the standard method for making the focal point of a golf ball. The method involves pouring a mixture of sap or elastic into a form, pressing it down with force, and letting it cool. It is doable to make different focuses promptly using a multi-hole structure and thought gear that controls the force and strain during the trim cycle.

4. Mantle and Cover Injection Molding

Molding the focuses of golf balls is followed by making the mantle and cover layers. The most customary strategy for making these layers is imbuement molding, which contains the high-pressure show of fluid material into a shape. To ensure exactness and consistency, precision imbuement molding machines are changed to make mantle and cover layers with the foreordained thickness and dimple plan.

5. Assembly and Encapsulation

Securing and Fixing Without the center, mantle, and cover, making a golf ball is difficult. Some golf balls have extra coatings or layers applied, like urethane or a straightforward completion, to work on their strength and appearance.

6. Finishing and Quality Control

Guaranteeing Quality and Last Subtleties The last strides in the creation cycle are cleaning and review. Before leaving the modern office, each golf ball is presented for wide testing and evaluation to promise it satisfies the creator’s necessities concerning gauge, weight, tension, and execution.

Golf balls can have surface imperfections like dimples or cover flaws recognized through robotized appraisal systems. As part of the review process, balls that don’t measure up are thrown out. Preceding being passed on to stores and clients, simply those that get through the exhaustive testing process are meticulously prepared.

Conclusion

How Golf Balls Are Made

Amazingly made and painstakingly manufactured golf balls are the result of a fascinating mix of science, development, and craftsmanship. The key to producing golf balls that perform best and last longest is a well-organized production process that begins with design and development and ends with quality control. Everyone can appreciate the craftsmanship and scrupulousness that go into making golf balls, from occasional weeknight fighters to prepared specialists. You could become familiar with this essential instrument by acquiring the expertise. I hope you like reading “How Golf Balls Are Made?”.

Jack Morgan is an experienced golf writer with over 8 years in the industry and a master’s degree in Sports Journalism. He combines his deep passion for the sport with his expertise to deliver insightful articles and updates for USAGolfDigest.com. Jack’s extensive background in golf journalism ensures that readers receive top-notch analysis and engaging content. Connect with Jack on Facebook to stay updated on the latest in the world of golf.

Very interesting details you have noted, appreciate it for putting up. “The biggest fool may come out with a bit of sense when you least expect it.” by Eden Phillpotts.